|

|

|

Page 5 |

Newsletter 118, Autumn 2017 © Hampshire Mills Group |

|

Wessex Flour Mill, Wantage

Ruth Andrews,

pictures by Keith Andrews |

|

Wessex Mill Clarks (Wantage) Ltd now

operate what is believed to be the smallest

roller-milling still in commercial use in the UK.

Nevertheless it now processes 30 tons of wheat a

day, 5 days a week, with 35 staff working two shifts

a day, 16 hours in total, and producing flour at the

rate of 2 tons per hour. 800-900 tons of wheat are

stored on-site at any one time. Its 29 varieties of

flour are sold wholesale worldwide to craft bakers

and directly to the public. It is clearly a very

thriving business. 10000 tons of wheat are grown

and collected yearly from a 30-mile catchment area;

in addition about 10% of Canadian wheat is also used

as it is a harder grain with the higher gluten

content needed for bread making.

|

|

Grain straight from

the combine harvester is cleaned in a venerable

Robinson separator (above) which uses airflow and

sieves to remove straw, clods of earth, stones and

so on, and in a much more modern cylindrical trieur

separator (right) which removes non-wheat seeds.

|

|

|

The grainís moisture

content is then adjusted (conditioned) 24 hours

before it is transported in modern pneumatic

conveying pipes to the 1935 Henry Simon roller

mills, which came from a mill in Glasgow which

closed. These 80-year old machines run slowly and

quietly with the minimum of maintenance, which means

that the flour produced isnít heated as much as in a

more modern plant. This has allowed the mill to

establish a very successful niche market as its

flour has a significantly different taste which

appeals to craft bakers.

|

|

|

Mill

manager Richard Sampford who showed us round very

kindly opened several of the working roller sets to

show us the different stages of breakdown of the

grain. The mill has 4 fluted break rolls to allow

wheatgerm and bran to be extracted and 8 smooth

reduction rolls to gradually turn the endosperm into

semolina, middlings, and ultimately flour. After

passing through each roll the different sizes of

particles are sieved in the plansifters upstairs.

The picture below left shows the result of the

sieving.

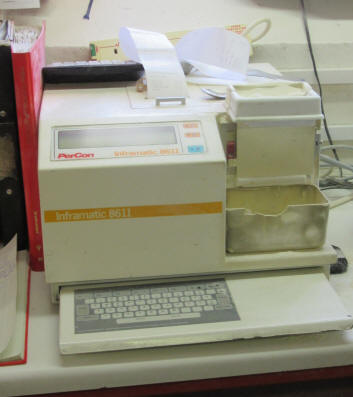

The

flour is tested hourly using a near-inframatic

analyser (below right) to monitor protein

content, moisture, colour, and so on.

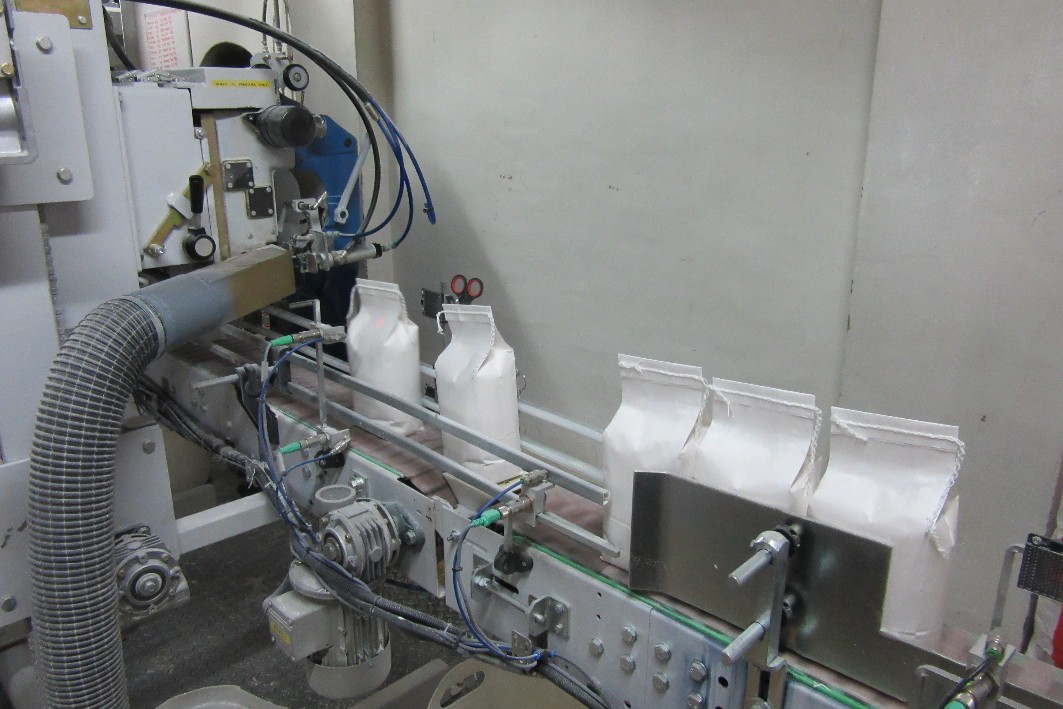

Once the flour has

been produced it is blended, after which it is

weighed, bagged (in pre-labelled 16kg sacks for

wholesale and 1.5kg bags for public sale), stitched

(both sacks and bags), and date-stamped. All the

machinery used for these processes is modern and

custom-built, although quite a few of the 29

varieties of flour have additional ingredients which

are mixed manually in small batches.

|

|

|

|

|

|

I would like to

thank Richard for giving us such an informative and

thorough tour, also the various staff members who

allowed us to get in their way and obstruct

progress. Congratulations and thanks to Sheila

Viner for arranging such a fascinating visit. The

mill can only easily handle groups of 10 or less.

For more information

about

Wessex Mill Clarks (Wantage)

Ltd, all the flours they produce, and the history of

the Munsey family who own the business visit

wessexmill.co.uk

|

|

|

Sacks and bags showing the large number of varieties

of flour,

and the eye-catching design on them

which features King Alfred, who was born in Wantage

|

|

|